TEDA advances efforts in energy cascade utilization, water resource optimization, and waste recycling to driving the growth of green circular economy.

Energy Cascade Utilization

Cabot Waste Heat Recovery and Utilization

The Cabot Chemical (Tianjin) plant is a global flagship facility of Cabot and a benchmark for sustainable development in the carbon black industry. By fully recovering and reusing waste heat from tail gas generated during the production process, the plant has not only effectively addressed tail gas emissions and reduced environmental pollution but also significantly lowered the company’s operating costs. Additionally, the Cabot plant supplies the recovered surplus steam to other enterprises, promoting green development within the industrial park.

Sinopec Tianjin LNG Project Puts China’s First Cold and Heat Energy Exchange Station into Operation

In November 2024, Sinopec launched the country’s first cold and heat energy exchange station in the TEDA Nangang Industrial Zone. Located within Sinopec’s Tianjin LNG receiving terminal, the station has an annual processing capacity exceeding 2.6 million tons. It marks China’s first achievement in energy coupling between an LNG terminal and surrounding large-scale petrochemical production facilities, with a cold energy conversion efficiency of over 95%, ranking first in the country for cold energy utilization efficiency.

Tianjin Nangang LNG Cold Energy Comprehensive Utilization Demonstration Project (Cold Energy Project of Sunpower Tech)

With a total investment of 1 billion yuan, the Sunpower Tech’s Cold Energy Project will fully leverage the abundant cold energy resources and chemical industrial advantages of Sinopec’s Tianjin LNG receiving terminal and Beijing Gas Group’s Tianjin LNG receiving terminal in the TEDA Nangang Industrial Zone. It aims to produce low-cost liquid oxygen, liquid nitrogen, and liquid argon, while establishing an integrated energy utility island that combines electricity, heat, cooling, and industrial gases. The project is set to become a world-class demonstration benchmark for the cascaded utilization of cold energy.

Good Use of Water Resources

TEDA has actively established a recycled water reuse system, implemented seawater desalination projects, and encouraged sewage treatment plants to adopt high-efficiency and low-energy consumption equipment, achieving remarkable results in the intensive use of water resources.

TEDA Landscape Lake at Urban Plaza (Recycled Water Reuse)

The planned area of TEDA Landscape Lake Park at Urban Plaza is approximately 89,000 square meters. Centered around the lake, the park incorporates designs such as permeable pavements and rainwater collection pools to purify rainwater, which is then channeled into the lake through pipelines. It serves as an immersive urban oasis that integrates ecological demonstration, leisure and entertainment, and cultural experiences.

Xianda Seawater Desalination Project

The Xianda Seawater Desalination Project is a key cooperation initiative between China and Malaysia under the Belt and Road Initiative. It is the largest seawater desalination project in northern China and the largest dual-membrane seawater desalination project in the country. As the sole planned industrial water source for the Nangang Industrial Park, the project will fully meet the water demands of all clients within the park.

Waste Recycling

TEDA enhances resource recycling to drive the green and low-carbon transformation of manufacturing. It supports enterprises in transitioning toward low-carbon, circular, and cleaner production, achieving the goals of reduction, resource recovery, and reuse as the circular economy calls for.

Steel Waste Utilization of Railbow Hills

Tianjin Rainbow Hills Cast Iron Co., Ltd. was established in TEDA in 2003. The company uses scrap materials from the production process of Toyota Motor Corporation, smelted and made them into steel ingots, and then supplies these to Toyota Mold as raw materials. It became the first enterprise in China to utilize scrap materials for steel casting.

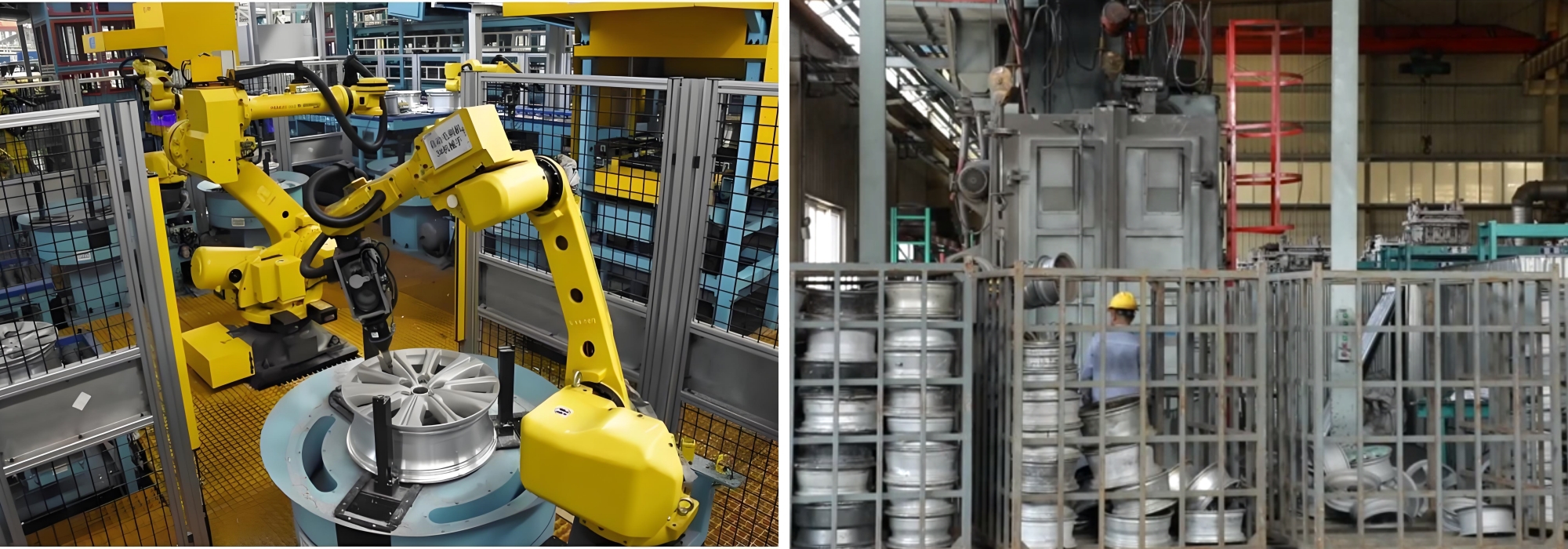

Lizhong Wheel Waste Aluminum Utilization

Tianjin Lizhong Wheel Co., Ltd., a leading wheel manufacturer in China, specializes in the R&D, production, and sales of mid-to-high-end aluminum alloy wheels. The company purchases discarded aluminum alloy wheels from the market and processes them into raw materials for molten aluminum. Currently, some of its products use up to 75% recycled aluminum, with 40% of the raw materials sourced from externally purchased scrap wheels and 35% from in-house recycled waste, achieving efficient resource recycling.

津公网安备 12019002000128号

津公网安备 12019002000128号